Product Introduction

[FPD-related Finishing Machines] Grinders for Light Guide Plate (Mirror Finishing Machines for Plastic Plates)

All Products- Product Name

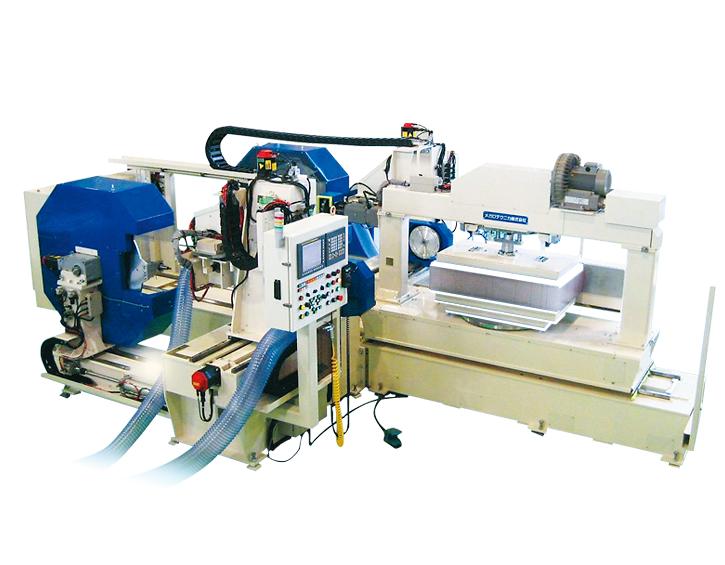

NC multiple machine (Mirror finishing and grooving)

- Type

- NCPB150F-2A・NCPB120F-2A・NCPB90F-2A・NCPB65F-2A

- Use

- Four-sided mirror finishing and grooving machine for light guide plate and diffuser plate

Maximum processing size: Supports up to 150 inch extra-large size.

Product Features

■ Continuous mirror finishing and grooving processing realizes high processing accuracy and productivity.

■ All the grooving adopted the side cutter system, and realized a significant reduction in processing time.

■ Automatic tool change (ATC) with 8 pieces of cutting tool.

■ 2A type can process grooving on two end faces simultaneously. (1A type is also available)

[Option]

■ The upper jig lift, automatic positioning and 250mm clamp stroke make workability outstanding.

■ Air-floating table saves labor at transportation.

■ Air-floating function and a powerful clamp jig with a dimension switching attachment.

■ A router blade is available for sample processing.

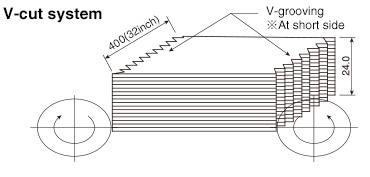

■ "V cut system" can process V groove for LED with high efficiency.

■ All the grooving adopted the side cutter system, and realized a significant reduction in processing time.

■ Automatic tool change (ATC) with 8 pieces of cutting tool.

■ 2A type can process grooving on two end faces simultaneously. (1A type is also available)

[Option]

■ The upper jig lift, automatic positioning and 250mm clamp stroke make workability outstanding.

■ Air-floating table saves labor at transportation.

■ Air-floating function and a powerful clamp jig with a dimension switching attachment.

■ A router blade is available for sample processing.

■ "V cut system" can process V groove for LED with high efficiency.